What is Insulation in Cable?

Ethernet cable is constructed with various different parts and materials. Insulation in ethernet cable is one of those components. Insulation in cable has various important functions and it is valuable to know more about it. In this article we will go over what is insulation in ethernet cable?

Insulation is defined as a way to isolate the flow of current by preventing direct contact between conductors and also a conductor and its environment. As you might know from other articles is that copper wires inside cables can cause crosstalk between them and the further apart they are the greater. Now to be able to do this in a cable insulation material was created. Insulation material is wrapped around each copper wire in the cable.

What is the Insulation made of?

Insulation on most wire and cables nowadays is made of one or more plastic compounds/materials. The insulation is applied by multiple methods. The popular choice in cable insulation is extruded polymers because they are shown to be:

- Functional

- Dependable

- Cost effective in manufacturing

Insulation Performance

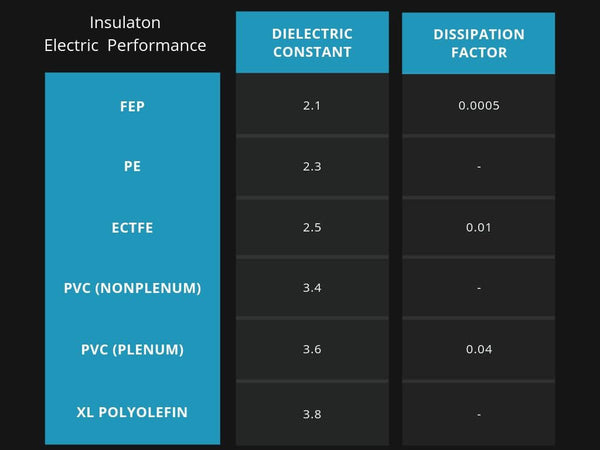

Twisted pair cable's performance relies on many different factors and insulation is one of them. As we noted before it is better to have the wires separated from each other to reduce cross-talk and interference between them. With insulation the copper cables performance has an opposite relation to the insulation dielectric constant and dissipation factor. So that means for greater performance in ethernet cables you want a lower dielectric constant and dissipation factor. In addition to that they will have lower attenuation and lower capacitance.

Material Components

Throughout history telecommunications cables have had their conductors insulated with compounds such as PVC (Polyvinyl Chloride) and PE (Polyethylene). PVC cables are usually the ones you find in inside plant cables and PE for cables that are often used in outside plant. The key thing to note is that PE insulated conductors are better for transmission purposes. The downside is that they are not suitable for indoor except if they are wrapped in fire retardant jacket compounds.

With those in place materials have come out to improve upon these insulation materials. One of these i quite common to ethernet cables and they are:

- FEP (Fluorinated Ethylene Propylene)

- Ethylene (Chlorotrifluoroethylene)

Hopefully I didn't misspell that ! These new compounds were brought in to coincide and improve on the previous mentioned compounds. The additional benefits with these materials is that they create lower smoke and reduce the spread of flames.

These terms stand for:

- FEP (Fluorinated Ethylene Propylene

- PE (Polyethylene)

- ECTFE (Ethylene Chlorotrifluoroethylene)

- PVC (Polyvinyl Chloride)

- XL (Cross Linked)

It's important to mention here that these numbers are affected by rises in temperature. As with most things temperature rise has an affect on performance or durability and for cable insulation it does have some affect. Some of these insulation compounds work better than the other in temperature rise and we will touch more in depth on that topic at a later date. For now it's important to know that FEP which is used in ethernet cable does a better job than PVC as temperature rises. Dielectric effects of insulation have reactions on the cables attenuation when frequencies increase.

Keep in mind here that this is the insulation compound and not the jacket material or fire rating. Ethernet cables such as Cat5e and Cat6 are made with different types of fire retardant such as PE and PVC which then makes them riser or plenum rated cables. These jacket material do not correlate with the information above.

Conclusion

We hope you found this article on what is insulation in cable helpful. Cable performance relies on numerous factors for it to go right. From the selection process to the termination process cables performance can differ. We hope this article informs on the various insulation compounds in cables. As temperature rises it might be worth looking into cables that are insulated with PE or FEP as attenuation remains lower at higher temperatures than PVC.